How to Build a Bookshelf in 7 Simple Steps - Handtool-Only Bookshelf Build

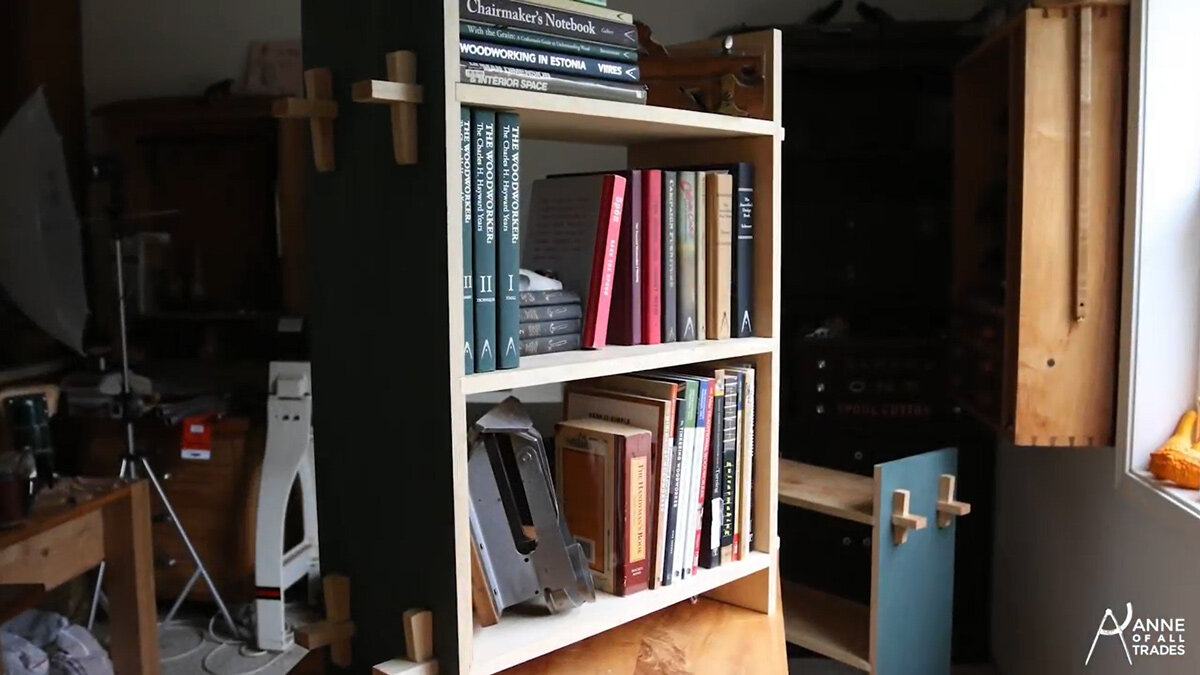

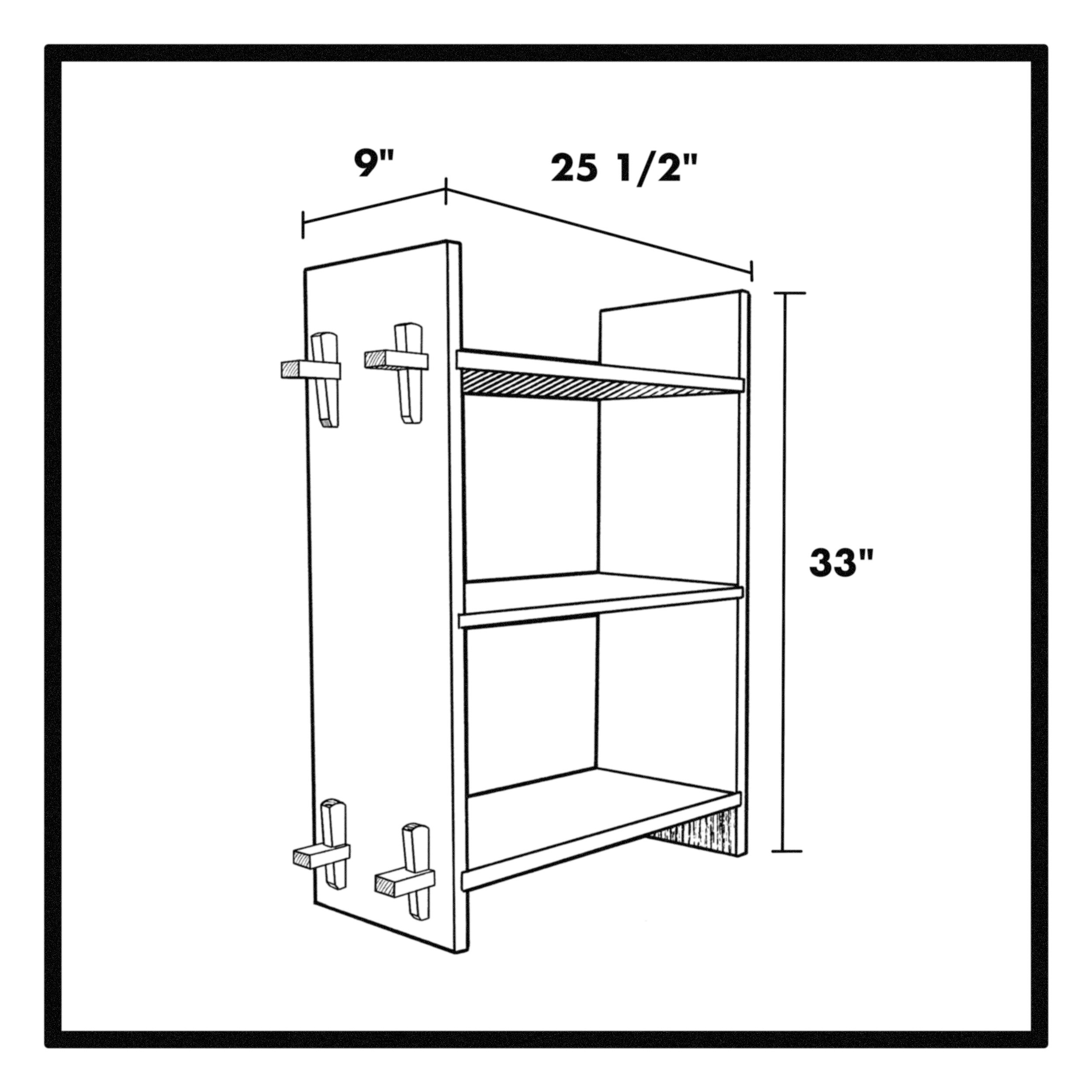

Learning how to build a bookshelf is a great skill most everyone will benefit from. This Japanese-style Tusk bookshelf (so named because of the Tusks that secure the joints) is one that requires very few tools, skills or supplies and is a great skill-building project for hand tool users resulting in a beautiful piece of furniture that will last a lifetime.

Two years ago, I was honored to be invited to teach at the Port Townsend School of Woodworking. I taught a basic joinery class, in which we built a Japanese- Inspired Collapsible bookshelf. I had to build one to prepare for the class, so I decided to bring along a camera while I did. This is a great project to practice all kinds of woodworking joinery including hand-cut dadoes, mortise and tenon, and, with a few simple design modifications, dovetails.

From a couple of pieces of solid wood and a few basic tools, you can create a beautiful masterpiece that would grace any home.

My good friend, Josh Nava has even drawn up the plans for this bookshelf, for those who want this project to be even easier.

You can find the Japanese-Style Tusk Bookshelf plans here.

Materials Needed

2, straight (no cupping or twisting) 8’ 1x12 Pine boards (Available at any home center)

Or Hardwood of your choice in similar dimensions

Tools Needed

Auger and 3/4” Bit (or drill and forstner bit

Mallet

3/4” Chisel

Back Saw

Coping Saw

Carpenter’s Square

Double square (if you have one, otherwise, any small square will do)

block plane

Oh! Did you know we have a secret club? You don’t need a secret handshake or password…just a quick click to join the secret world of folks with sharp tools! Josh Nava and I have been teaching live classes through Zoom. “How To Sharpen Anything” is a great primer for hand tool users- newbies and experts alike- that want to get more out of their tools. Sharpness helps in every wood working project and again, the coolest part is being in the secret club!

Step 1: Marking the Mortises

OK, You caught me. I cheated a little. I used… GASP… the tablesaw to do it. You can be a better purist than me by starting with the REAL step one, cutting the sides of your bookshelf to length, (use a panel saw and clean up with your block plane) deciding on your shelf placement, and cutting your dadoes. Cut those dadoes by cutting the top (showing side) of the dado line with your back saw- you might have to cut in from both sides and meet in the middle). My dadoes are 1/2” deep. Then, using your 3/4” chisel perpendicular to the line, chop down to the 1/2” depth along the entire line in 1/4” increments. Clear the waste with your chisel. Voila, a dado!

The mortises that will contain the tusks (or the keys) which are the signature aesthetic and strength features of this piece.

To mark out the mortises for the tusks, I’m using two sets of dividers. One set to the inner dimension of the wall of the mortise, and one set to the outer dimension of the wall of the mortise.

I use a double square to carry the edges of the dado around the case so I can gauge where to cut the mortises on the opposite side of the case. I mark both sides.

When it comes time to cut the mortise, I’ll start my mortise on the face, or outward-facing side of the mortise and cut inward toward the dado. When I’ve cut ¾ of the way through, I’ll flip my piece over and finish from the dado, or non-showing side.

My reasoning here is if unsupported grain breaks away during the mortising process, it will be on the hidden, rather than the showing side of the joint.

Careful layout at this stage is crucial, and a few extra moments taken here will pay off big with crisp beautiful joints later.

Step 2: Mark out the Tenons

The tenons will protrude outside the carcass and capture the tusks, or keys, and lend strength to the bookshelf.

It’s at this step we decide just how far the joinery will protrude from the case and the final dimension of the shelves. The middle shelf is marked and cut to the same length as the top and bottom shelf, minus the tusks.

I will cut the tenons before the mortises because, if I make a mistake on my tenons, I can simply adjust the position of my mortises. But hopefully, everything will go smoothly and you can use the initial mortise layout.

Step 3: Cut out the Tusks

Tips on Sawing Techniques: Have your piece firmly clamped square in the vice, just slightly higher than the depth of the tenon you’re cutting. This is so you can get the most bite out of your vice and reduce as much chatter from the saw as possible. (Be sure to watch the YouTube video to say hello to my shop cat, Oliver!)

Start your cut on the radius of your thumb at the tip of the saw and gently push the saw forward.

Make all vertical cuts with a backsaw, cut out the middle of the waist with a coping saw, then flip the piece on edge to remove the corner pieces.

Rubbing beeswax on your saw is a fantastic way to lubricate the cut, prevent the saw plate from heating, and provide long-term moisture protection for your tools (mutton tallow also works well here).

Body position is important, I have my non-dominant foot forward, and my non-dominant hand resting on the work. This tripod position gives me strength and stability and ensures there is no weight being pressed on the back of the saw.

Gravity and the heavy brass back of the saw will do everything you need to get the saw through the cut. You don’t need to push down.

Move your body out of the way and grab the handle of the saw handle lightly, pretending it’s a baby bird I don’t want to crush. All you have to do is move the saw back and forth and it will stay on the line.

Since these joints will be captured in the dado and won’t show, they don’t need to be pretty. I do, however, want to be sure there aren’t any proud areas in the joint that will prevent it from seating fully, so I’ll chisel out any waste that’s left above the saw-line.

Step 4: Waste Removal of the Mortises

Choose the widest Forstner bit that will fit within the mortise layout and drill two, side-by-side holes from both sides of the wood, so as not to blow out any of the grain on either side of the cut.

Clean up the mortises by chopping out the remaining waste with a ¾ inch chisel. Be very cautious when chiseling out your waste, remember to start on the show-side, then flip and remove the rest of the waste on the dado side.

Use your finger as a stop-block so you don’t slip and mar my bench-chop, but if you’re not confident with this technique, using a chopping block beneath your piece is helpful.

Clamp your pieces down firmly just over the legs of your bench. This means as you’re chopping, there won’t be any flex, bounce or movement, minimizing each chop.

Step 5: Chop Mortises and Key Tenons

Assemble the carcass with the tenons poking out, then lay the key over the tenon and decide where it looks good to let the key set. Mark out a line where you’ll want the key to line up, then use the key (or tusks) as the layout guide to mark the angle where you’ll angle the mortise. Mark the back of the mortse as well.

Once you mark out the angled mortses on the tenons to accept the key, drill out the majority of the waste from both sides with a Forstner bit, then chop the rest by hand.

The layout line we made with the tusk for the angled outer edge of the mortise acts as a fantastic visual guide for this part of the process. If you remembered to assemble your carcass and mark the back of your angled mortise on the exterior of the bookshelf, you won’t accidentally undercut your entire mortise as I did!

Step 6: Dry Fit Your Bookshelf

Take each component of the bookshelf and assemble the bookshelf to see if any adjustments need to be made.

If you’re happy with how everything fits, then it’s time to clean up all pieces and get them ready to assemble for good.

This is when you will use a wet cloth and an iron to remove any dents, do any finish planing on the planks, chamfer any edges that need it. Basically, you’re just getting the piece ready to finish.

It’s also at this point that you would add any paint or wood finish to your pieces, allow them to dry completely, then move onto the final assembly.

Step 7: Assemble Your Piece

Just as you did with the dry fit, assemble your piece together, place it in your office, home, or workspace and fill it with books!